Fire Testing in Australia’s Building Industry: What You Need to Know

by Patrick Motteram

Australia’s building and construction sector is large, dynamic, and constantly evolving, driven by new materials, products, and system innovations. From the latest insulation and cladding panels to re-engineered wall systems, these developments often require performance verification under heat or fire conditions to meet regulatory standards.

In this article, we outline why fire testing is critical, how it’s defined by the National Construction Code (NCC), and what suppliers need to understand before bringing a product to market.

Why is fire testing required?

The NCC outlines strict performance expectations for materials, products, and systems used in specific building classes and applications. These expectations include one or more prescribed test methods to assess fire performance under controlled conditions. The test method(s) for each application are carefully chosen so that the conditions of the test appropriately challenge the particular behaviour of the specimen(s) relevant to the application within a building.

Many building applications require multiple tests to assess different fire behaviours, such as ignition, spread of flame, structural integrity, and temperature rise.

Materials, products, and systems: what’s the difference?

Understanding how the NCC classifies fire performance begins with the distinction between:

- Materials (eg aluminium sheet)

- Products (eg aluminium composite panels)

- Systems (eg full wall systems using composite panels)

Each stage of assembly, from raw material to integrated system, may have separate fire testing requirements:

- Reaction to fire tests are typically used for materials and products.

- Fire resistance tests are used for full systems (e.g., walls, doors, floors).

For example, an aluminium composite panel may:

- Require combustibility testing of the core insulation material,

- Undergo additional testing of the assembled panel, and

- Be installed in a wall system that needs a fire resistance test.

Materials may be used independently or as part of a product which is used as a component of a system. For example, aluminium might be used independently in flat sheet form, or as part of a product such as aluminium composite panels, which are then used as part of a wall system. The NCC has certain expectations of aluminium as a material, different expectations of the composite panel and additional expectations of a wall system.

In the case of an aluminium composite panel, whilst the aluminium skin might be considered non-combustible, the insulating core material is also required to be tested as an independent material to determine its combustibility. The panel, as a product, is likely to require an additional test to evaluate specific fire hazard properties. These are Reaction to Fire Tests. The wall system requires determination of its fire resistance level using a Fire Resistance test method. Other tests may also be required.

Understanding the fire test process

Most fire test methods referenced in the NCC are defined in Australian Standards, developed by Standards Australia in consultation with industry experts.

A standard test method outlines three key components:

1. What is tested?

- The item is referred to as a sample or specimen.

- Strict specifications determine the size, construction, and condition.

- Example: AS 1530.1 requires a cylindrical sample with precise dimensions for combustibility testing.

- The sample or specimen requirements are described in detail and are often very prescriptive, allowing for little or no variation. For example, testing in accordance with AS 1530.1:1994 (R2016) for material combustibility requires six specimens “Each specimen to be 45 mm (+ 0 mm, -2 mm) in diameter and 50 mm (± 3 mm) in height, with a volume of 80 cm³ (± 5 cm³) with a 2 mm diameter hole 25 mm deep drilled centrally down the axis of the cylinder.” Other test methods require the specimen to be more representative of the actual use of the product/system in practice. A fire resistance test of a wall system is conducted on a 3 m × 3 m wall system incorporating features such as joints and fixings typical of those required in practice.

2. How is it tested?

- Methods specify orientation, restraint, and exposure.

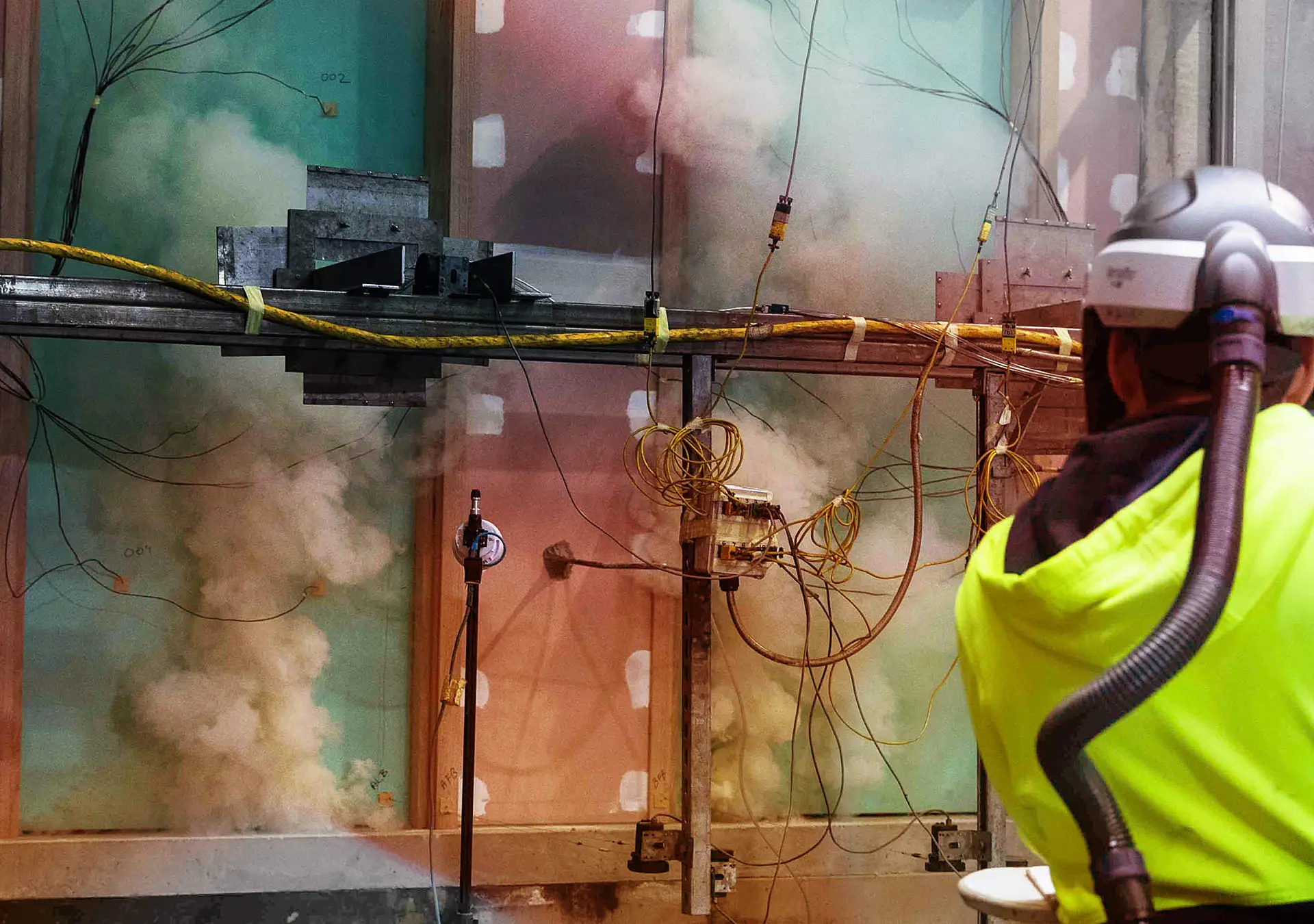

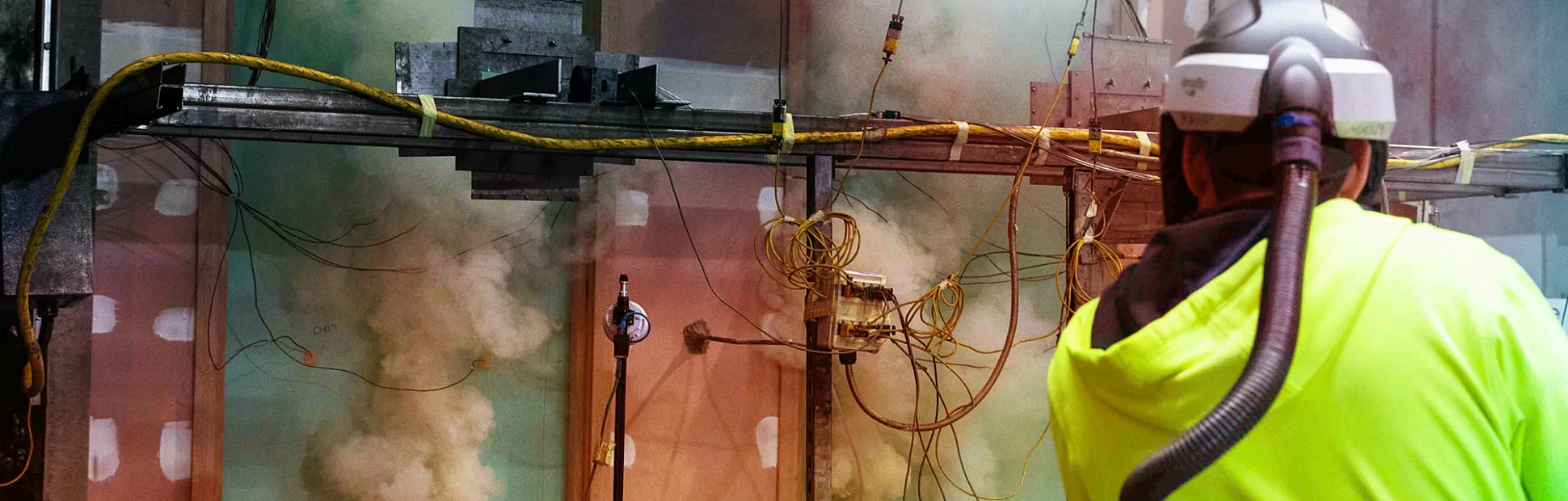

- The test method describes how a specimen should be oriented and restrained to allow for appropriate exposure to the test conditions. For example, specimens tested for combustibility are placed in a wire mesh basket and lowered into a small furnace with minimal clearance between the specimen and the walls of the furnace. In contrast, large scale fire resistance specimens are installed into a rigid test frame and mounted onto the face of a furnace such that the specimen is in intimate contact with the combustion conditions within the furnace.

- Temperature, pressure, and duration are tightly controlled, often following the standard (cellulosic) time-temperature curve.

- Exposure conditions such as temperature, pressure, and test duration are also specified in detail and generally have allowable tolerances. The exposure conditions in AS 1530.4 are commonly referred to as the standard or cellulosic curve which is a time-temperature curve representing a fire’s behaviour in a building over time. The pressure conditions within the furnace are different for different specimen types.

3. How is performance measured?

- Each test method has one or more “acceptance criteria” requiring certain observations and measurements to be made during the exposure period of the test, and sometimes during a post-exposure period. Observations of significant events are made directly by the laboratory staff and recorded immediately, and often further observations are documented following review of the test video recording. Measurements of temperature, pressure, time and key changes in specimen dimensions such as deflection of a wall system are made using appropriate, calibrated instruments and recorded through real-time data acquisition systems.

- Acceptance criteria may include observations of flaming (ignition) of the specimen, how long the flaming continues, to what extent does the flaming spreads, an increase in temperature, whether unacceptable gasps have opened in the specimen, etc.

- These observations and measurements are compared to the acceptable limits provided within the test standard.

Test reports, certificates, and confidentiality

The fire test process concludes with formal documentation:

- Test report: A detailed, factual record including setup, test conditions, results, and supporting data. It does not expire.

- Regulatory Information Report (RIR): A concise version of the test report, omitting proprietary details to protect intellectual property.

- Test certificate: A brief summary (e.g., product name, test standard, result) often used for marketing, but not acceptable as regulatory evidence under the NCC.

Key takeaways

- Fire testing is mandatory for many materials, products, and systems under the NCC.

- Test methods are not one-size-fits-all; multiple tests may be required.

- Only detailed reports and supporting documentation meet NCC compliance standards—not certificates alone.

- Working with an accredited testing laboratory ensures testing is valid, reliable, and recognised by regulatory bodies.

Need fire testing support or guidance?

Our NATA-accredited fire testing laboratory in Melbourne is here to help. Contact us today to learn how Jensen Hughes can support your compliance needs. You can learn more about our fire testing and assessment services here: Jensen Hughes | Fire Testing + Technical Fire Assessment