Jensen Hughes’ Innovative Interactive Platform for Remote Fire Test Witnessing

Fire testing is an integral part of the comprehensive services Jensen Hughes delivers worldwide. Our Australian fire testing laboratory is equipped with state of the art technology and accredited for compliance with ISO/IEC 17025, enabling the seamless execution of a wide range of fire tests.

Our suite of digital tools includes an automated furnace temperature and pressure control system, an advanced data logging system with four levels of simultaneous data backup using proprietary in-house software and a 4K audio-visual recording system. All systems are integrated through high speed networking protocols to ensure secure, real-time data capture, recording and sharing.

Among our many smart innovations, the lab also features IoT-enabled lifting machines, a smart local weather station, connected temperature and atmospheric pressure sensors and remotely operable test equipment.

One of our most significant advancements is our in-house developed, web-based remote witnessing application, an interactive digital platform that allows clients to experience fire tests remotely with the same level of engagement as being on-site.

The platform includes four key views:

- Furnace data

- Loading data

- Thermocouple groups

- Camera groups

Each of these provides real-time access to synchronised test data and live video feeds, accessible from anywhere in the world. The main page also displays the live test duration and ambient laboratory temperature and is compatible with every test we perform.

Furnace and Loading View

In a fire resistance test, the specimen is exposed to controlled high temperatures and constant pressure on one side. Relevant test standards, determination of the temperature and pressure exposure conditions and accurate control are essential for a valid outcome.

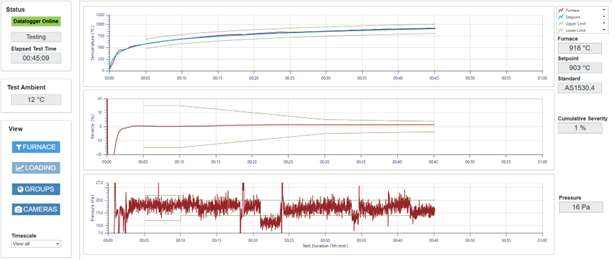

The furnace view of the remote witnessing application provides a graphically represented live view of furnace temperature, severity and pressure plotted against time. It also presents numerical details such as instantaneous average furnace temperature, set point temperature per the standard curve, test standard, cumulative severity and pressure. These details are extracted directly from the data logger and simultaneously transformed into the interactive remote witnessing application view. Access to this data enables our clients to verify that the test is being conducted in accordance with the standard, and that all temperature and pressure criteria are met throughout the duration of the test. An image of the furnace status graph is represented in the figure below.

Some tests require loading to simulate loaded structures that may influence the integrity of the tested system. The load is calculated based on the application and is applied for the duration of the fire test. The applied load can also be viewed under the loading section of the remote view application to ensure that the agreed load is applied to the tested system.

Thermocouple and Camera Groups

The insulation performance of a tested system is determined by measuring temperature on the unexposed side of the system. All temperature measurements of the tested system on the unexposed side are recorded and instantly transmitted to a live view of the temperature vs. time graph in the remote witness application.

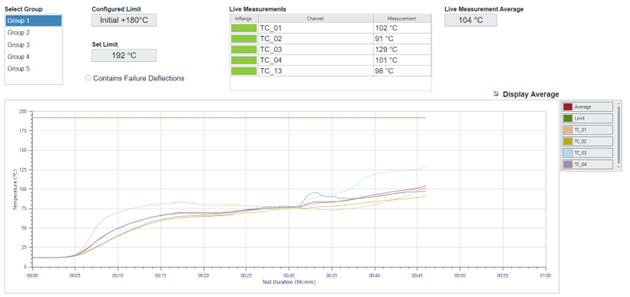

For convenience of data processing and understanding of the temperature behaviour, the thermocouples positioned at various locations on the unexposed side of the specimen are grouped. These groups and the thermocouple readings in each group are accessible through the application. Once control is given to the test sponsors, they can toggle between each group and understand how their specimen is performing.

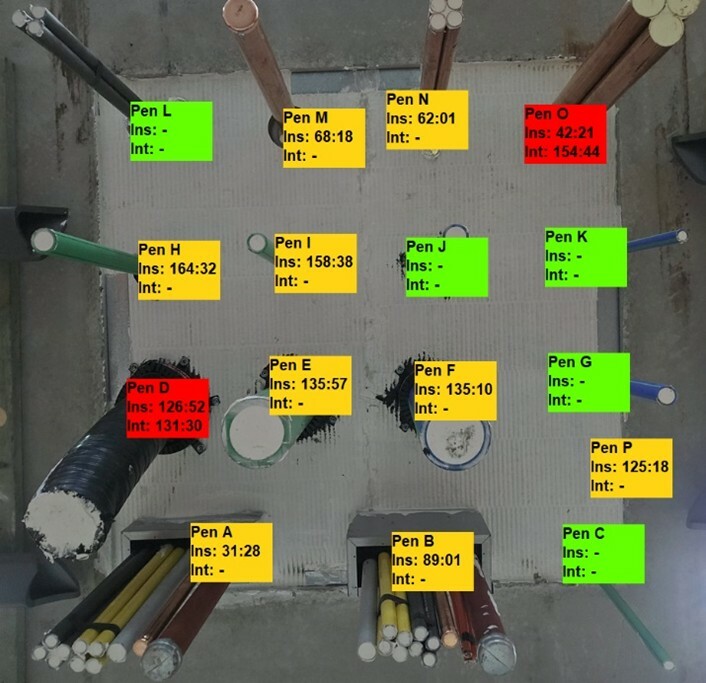

The failure criteria, as determined by the relevant standard, are pre-provisioned to the system and are visually represented in the app with color codes. For example, if a thermocouple is within the range of failure temperature, it will remain green and turn red once failed. Deflection measurements are also telecasted through the same app under different groups and are instantly accessible for verification. Even though the results identified from the application are not considered final, it enables the sponsors to understand the behaviour of their specimen during testing without being physically present. Corresponding images are inserted below.

The lab also has network-enabled UniFi cameras positioned across the lab, pointing to the area of interest. The cameras capture 4K videos. The remote witness app can be configured to include desired cameras, and our clients can easily toggle between the cameras to observe the specimen from various angles. Additionally, portable cameras can be placed in other locations as required by the sponsors.

Benefits of Remote Witnessing of Fire Tests

Offering live transmission and remote witnessing of fire tests delivers significant advantages for applicants and ensures greater transparency and efficiency in the testing process.

Enhanced Understanding and Real-Time Decision Making

Remote witnessing allows applicants to observe their specimen's behavior in real-time during the test. This live transmission helps our clients:

- Witness Specimen Behavior: See exactly how the product reacts to the fire, minute by minute, without relying solely on post-test reporting.

- Inform Immediate Judgments: Form own assessment of the results immediately. This is invaluable for deciding on further improvements to the product or for developing a precise assessment scope based on the observed performance.

This clear, real-time communication of data is critical, especially since fire testing standards often leave observation procedures and recording subjective and open to the interpretation of the lab. By witnessing the test live, a deeper understanding gained that can directly influence how the observations in the final test report are interpreted and outlined.

Improved Logistics, Scheduling and Cost Savings

The ability to join the test remotely also provides substantial logistical benefits, including

- Schedule Flexibility: Applicants who lack the time or ability to physically travel to the lab can easily witness the test, ensuring better time management for their team.

- Facilitated Testing: The test can be facilitated on schedule, without delays caused by travel constraints.

- Reduced Costs: Direct savings by eliminating the need for travel and accommodation expenses associated with physically attending the lab to witness the test.

Beyond Compliance: Setting the Benchmark

The Jensen Hughes remote witnessing application represents a significant advancement in fire testing services – one that goes beyond meeting minimum requirements to seamlessly bridging the gap between physical presence and virtual participation.

By integrating state-of-the-art laboratory technology with an intuitive, web-based platform, we provide clients with a unique level of transparency and control. The application's ability to deliver real-time, synchronised data, including furnace conditions, loading data and insulation performance, alongside high-resolution video feeds ensures that clients can monitor and verify critical aspects of a test from anywhere in the world. While the information provided by the platform is not the final test result, it empowers applicants to understand the real-time behavior of their specimens and confirm that all test parameters are being met. Ultimately, this interactive platform not only enhances client experience, but also reinforces Jensen Hughes' commitment to innovation, accuracy and client confidence in its fire testing services.