Fire Door Hardware: Performance Evaluation and Compliance Framework

by Alim Rasel

A fire door is a door with a designated fire-resistance rating, installed within a fire-rated separating element to help prevent the spread of fire between compartments. These doors are fitted with hardware that enables essential functions such as latching and closing, along with secondary functions including security, operational efficiency, and aesthetic appeal. This blog post outlines the compliance pathways for fire door hardware and details the services provided by Jensen Hughes to support achieving that compliance.

What is Door Hardware

Door hardware refers to the collective components or devices that are attached to or used in conjunction with a door. This can come in the form of a latchset, closer, door viewer, hinges or other surface furniture.

Regulatory Pathways for Compliance

Clause S12C2 of NCC 2022 requires that fire doors and associated components comply with AS 1905.1. As per section 3 of AS 1905.1:2015, the fire resistance of a doorset must be established through testing in accordance with AS 1530.4:2014, section 7. Additionally, the standard specifies that the fire resistance performance of door hardware and other components must be assessed in accordance with Sections 2 and 4 of AS 1905.1:2015.

Section 2 of AS 1905.1:2015 outlines the design requirements for fire doors, while Section 4 details the minimum testing criteria for door hardware. These criteria may involve full-scale testing, pilot-scale testing, or, in some cases, compliance without testing, depending on the nature of the hardware and its application. Compliance in accordance with AS 1530.4:2014 and AS 1905.1:2015 for doorset and hardware can be demonstrated through evidence of suitability pathways outlined in NCC. These pathways are discussed in the following section.

Evidence of Suitability Pathways for Compliance

The suitability framework for evaluating fire resistance is set out in the National Construction Code (NCC) as follows:

Suitability – A5G1

With reference to clause A5G1, building installation must use materials, products, and construction methods that meet NCC requirements and are fit for their intended purpose. A product or building element meets this standard if it complies with A5G3.

Evidence of suitability – A5G3

The conditional phrase "Subject to" at the beginning of A5G3(1) means that the subsequent forms of evidence do not take precedence over the condition set by this clause. In the case of fire performance of fire doors and door hardware, A5G5 is the relevant governing requirement for fire resistance, and any evidence of performance must satisfy A5G5 to satisfy A5G3. This means, for example, a product technical statement for fire rated door hardware does not meet the requirements of evidence of suitability.

Fire-resistance of building elements – A5g5

For a product or system where the Deem to Satisfy (DtS) provisions require the building element to have a fire resistance level (FRL), it must be determined in accordance with S1C2.

Specification – S1C2

Door hardware meets the requirements for determining the FRL if it is identical to a tested prototype as per S1C2(b) or different to a minor degree from a prototype tested as per S1C2(c). In both cases, the performance must be confirmed in a report from an accredited testing laboratory (ATL). Such a report serves as evidence of suitability for the determination and demonstration of performance and:

- Demonstrates that the material, product, or form of construction meets specific NCC requirements; and

- Details of the tests conducted, results obtained, and any supporting information used to substantiate compliance.

Principle Behind Door Hardware Assessment

Fire doors are tested for their FRL in accordance with AS 1530.4. When new hardware is proposed—either as a replacement or an additional alternative to the tested system— its impact on fire performance must be evaluated. It must be assessed through either pilot-scale or full-scale testing, as outlined in Section 4 of AS 1905.1.

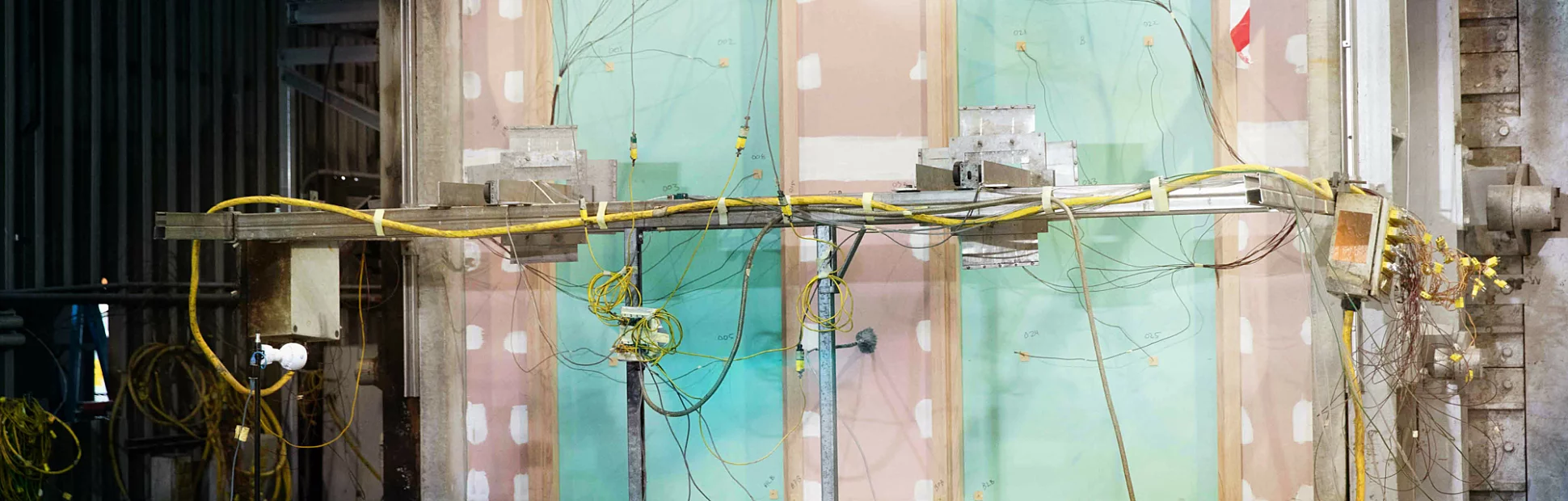

The test door is typically constructed to match the baseline door, utilising the same core material and leaf assembly. In pilot-scale testing, the door may be reduced in size to accommodate the testing apparatus. If the proposed hardware was found not to adversely affect the fire resistance performance of the test specimen for a specified duration, it can be established that the baseline door will exhibit equivalent performance when fitted with the same hardware. The test results are then used to determine a combined FRL for the baseline door incorporating the new hardware.

Jensen Hughes Added Value

Jensen Hughes Fire Testing is a NATA-accredited laboratory offering fire testing services, including testing to AS 1530.4 and other international fire resistance testing standards. In addition to laboratory testing, Jensen Hughes has a dedicated team of engineers who conduct fire assessments in accordance with relevant standards, procedures and assessment protocols such as AS 1530.4:2014, AS 1905.1:2015 and NZS 4520. As a NATA ATL, reports from Jensen Hughes meet the evidence of suitability requirement of A5G3 1(d) of NCC 2022, subject to A5G5.

Jensen Hughes' integrated approach ensures comprehensive compliance support, providing consultation and advice before carrying out testing and by offering both test and assessment reports that fulfil evidence of suitability needs. This ultimately facilitates easier administration of NCC compliance for designers, builders, and building surveyors, enabling them to confidently navigate this area and, additionally, minimise the testing required from a manufacturer's or supplier's perspective, given that door hardware is offered in multiple variants and models.

Specifically for door hardware—traditionally, door hardware was tested individually either in pilot or full-scale tests—with separate reports issued for each item. With the introduction of NCC 2022 and its requirement to use the latest testing standard—in this case AS 1530.4:2014—fire door designs have evolved, resulting in two distinct generations of doorsets. This change means that each hardware item must now demonstrate compliance across both generations, making the traditional approach increasingly complex and resource intensive.

To address this, Jensen Hughes offers the Master Door Hardware Assessment Report (MDHAR), a consolidated report that compiles relevant performance outcomes for a range of hardware products across both door generations. This streamlined approach reduces administrative burden, lowers compliance costs, and simplifies the regulatory review process.

Conclusion

Fire compliance of fire door hardware under the NCC and relevant Australian Standards demands thorough testing and clear evidence of suitability. Jensen Hughes simplifies this process through accredited testing, expert assessments, and the Master Door Hardware Assessment Report (MDHAR), which consolidates compliance data across door generations. This streamlined approach reduces complexity, lowers costs, and supports efficient regulatory approval.

Alim Rasel

Alim Rasel is a senior fire assessment engineer currently based in Brisbane, Australia. Alim specialises in conducting comprehensive fire assessments for a diverse range of construction elements. His areas of expertise encompass doorsets…