Why Dust Explosibility Testing is Critical for Safety + Compliance

by Parker MacNeil

Combustible dust explosions pose a serious and frequently overlooked risk in industrial settings. While many organizations understand the importance of housekeeping and exhaust ventilation for dust control, the true hazard of combustible dust particulate is often underestimated. This is typically due to a limited understanding of dust explosibility parameters and how to interpret and apply test results correctly.

Combustible dust hazards vary widely, as dust explosibility parameters are not intrinsic properties. While the chemical composition of a dust largely dictates its explosibility, physical factors including particle size, particle shape and moisture content have a significant impact. A given dust sample can exhibit drastically different dust explosibility parameters when tested at smaller vs. larger particle size distributions or at lower vs. higher moisture contents. For this reason, explosibility parameters for dusts are not always well defined in literature and should be determined through material-specific testing.

Establishing the need for dust explosibility testing is only the beginning, as multiple consequential decisions must be made that may significantly impact the test results and how the data is applied. These decisions include identifying the appropriate materials to test, the proper sampling locations, the appropriate tests to perform and the appropriate test conditions for the material. Performing the appropriate tests under the correct conditions will lead to obtaining data that can be used to support effective management and mitigation of combustible dust hazards.

Important Dust Explosibility Parameters

Various dust explosibility parameters are used to identify and evaluate combustible dust hazards. These explosibility parameters can be obtained through testing protocols published by ASTM International or other organizations. Common explosibility parameters used to quantify the ignition sensitivity and explosion severity of dusts are summarized below.

- Explosion severity. The explosion severity parameters include the maximum explosion pressure (Pmax), maximum rate of pressure rise (dP/dt)max and dust deflagration index (Kst). Dusts are classified according to their deflagration index which provides a measure of the relative explosion severity compared to other dusts. The explosion severity parameters can be used to evaluate the potential severity of a dust explosion and are used for the design of explosion protection safeguards.

- Minimum explosible concentration (MEC). The MEC is a measure of the minimum concentration of dust (g/m3) that when dispersed in air, will propagate a deflagration when ignited. The lower the MEC value, the greater the ease of formulating a combustible dust atmosphere.

- Minimum ignition energy (MIE). The MIE is the lowest capacitive spark energy (mJ) that will cause a dust cloud to ignite and propagate flame. The MIE is an important factor in evaluating the potential for dust cloud ignition due to electrostatic spark discharges developed during material transfer or from equipment.

- Minimum ignition temperature (MIT). The MIT is the lowest temperature (°C) of a hot surface that will cause a dust cloud to ignite and propagate flame. The MIT is an important factor in evaluating the ignition sensitivity of dusts and is relevant for defining the maximum operating temperatures for mechanical and electrical equipment in environments where combustible dusts are handled.

- Layer ignition temperature (LIT). The LIT is the minimum temperature (°C) at which a layer of dust of specific thickness is ignited by a hot surface. The LIT is used for defining the maximum operating temperatures for mechanical and electrical equipment in environments where combustible dusts are handled.

These dust explosibility parameters can be used to assist in determining the likelihood and severity of a dust explosion event. It is important to note that it is not always necessary to determine all of these parameters for a given dust sample. However, it is crucial to determine the necessary parameters to validate the safety basis for a specific process operation or facility.

Factors Affecting Dust Explosibility

Dust explosibility parameters are impacted by various physical factors, including particle size, particle shape and moisture content. In general, dusts with smaller particle size distributions and lower moisture contents will exhibit greater explosion severity and will be more sensitive to ignition as summarized below.

Variable | Pmax | Kst | MEC | MIE | MIT |

|---|---|---|---|---|---|

Decreasing Particle Size | Increases | Increases | Decreases | Decreases | Decreases |

Decreasing Moisture | Increases | Increases | Decreases | Decreases | Decreases |

Effect of Particle Size + Shape

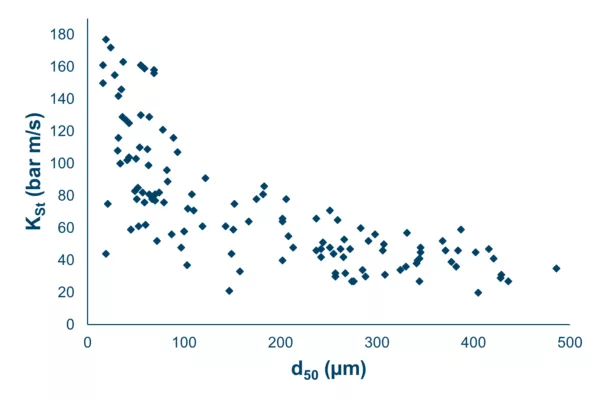

The particle size distribution of dust has a significant influence on dust explosibility as smaller particles present a larger specific-surface area. Particle shape also has an effect as irregularly shaped particles can exhibit a larger specific surface area than spherical particles. As dust explosions are combustion-oxidation reactions, a larger specific surface area exposes more material to oxygen and increases the rate of heat transfer and combustion at the surface. Smaller particle sizes lead to faster combustion rates which results in a faster rate of pressure rise (dP/dt)max, and a higher Kst. This is illustrated in Figure 1 which includes data for 126 wood dust samples tested by Jensen Hughes at varying median particle diameters and moisture contents below 5% by weight.

As shown in Figure 1, wood dust samples with smaller particle sizes tend to exhibit higher Kst values. This trend is also consistent for other organic and inorganic dust particulates. With respect to ignition sensitivity, finer dusts are more sensitive to ignition and exhibit reduced MEC, MIE and MIT parameters meaning that lower quantities of dust and lower ignition energies are required to result in a dust explosion.

Effect of Moisture Content

The moisture content of a dust also plays a critical role in explosibility. The specific role of moisture in reducing both the ignition sensitivity and explosion severity of dust clouds is complex. First, water has a high heat capacity and acts as an inherent heat sink as it absorbs heat from an ignition source. Second, moisture must evaporate before the particles can ignite which consumes a significant amount of energy. Third, moisture content increases agglomeration and reduces the availability of fine particle dispersion [1].

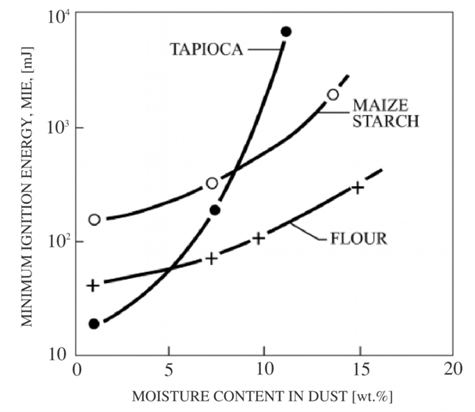

In general, as the moisture content increases, the explosion severity and ignition sensitivity of the dust decreases. The effect of moisture content on the MIE of various dusts was demonstrated in the work of van Laar and Zeeuwen [2] as shown in Figure 2.

ASTM Testing Protocols

To combat the effects of particle size distribution and moisture content, the testing standards published by ASTM International recommend that dust samples are tested at a particle size distribution of at least 95% minus 200 mesh (75 µm) and at a moisture content of less than or equal to 5% by weight. This results in conservative dust explosibility parameters being obtained for the tested materials such that the worst-case parameters can be accounted for. However, the ASTM standards also outline that it is appropriate to test material “as received” in certain situations when the material is representative of how the material is handled in the specific process. This is discussed in the following sections.

Determining Appropriate Test Conditions

When testing a dust, it is critical to determine if the sample should be tested “as received” or at more conservative test conditions. Testing the material “as received” refers to testing it at the conditions at which the material originates in the process. A sample can be tested “as received” in terms of particle size, moisture content or both. Selection of the test conditions requires careful consideration as less conservative explosibility parameters are typically obtained when a dust sample is tested “as received.”

In most industrial settings, dust that is handled or generated will have a particle size distribution comprised of both coarse and fine particles. When dust is suspended in air, larger particles will fall out of suspension due to gravity while the finer particles can remain suspended in cloud form for relatively long periods. This can lead to the formation of fine dust clouds inside process equipment or building compartments even when the material contains only a small fraction of fine particulate. The moisture contents of powders or dusts can also vary throughout a facility depending on the specific process stage or equipment, environmental conditions and other factors. With this in mind, the decision on how to test the material should include, but not be limited to, the following considerations:

- Where the “as received” material sample was collected from

- Particle size distribution of the “as received” material

- Moisture content of the “as received” sample and the typical variations

- Likelihood of producing fine particulate during handling (friability)

- Process equipment type and operations conducted (i.e., if the equipment will generate fines)

- Consistency of operating conditions and materials handled in the process

Testing materials “as received” may be appropriate in certain scenarios but requires careful consideration. When a material is tested “as received” in terms or particle size or moisture content, it is expected that the explosibility parameters will not be representative of the most severe conditions. This can lead to improper management of combustible dust hazards. Testing materials at the conditions outlined in the ASTM standards is beneficial as a facility or operation that is designed based on the conservative explosibility parameters will also be appropriate for the explosibility parameters of the material in the “as received” state.

Determining What Materials to Test

The number of different combustible dusts handled or generated can vary significantly depending on the facility or process in question. For example, a sawmill will typically only handle wood dust particulate (although the wood species may vary) while a pharmaceutical manufacturing facility may handle hundreds of different active pharmaceutical ingredients and excipients in powder or dust form. As such, numerous different combustible dusts may be handled in a specific facility area or process system.

With respect to dust hazard management, it is important to determine the worst-case explosibility parameters so that the facility or process is appropriately designed for operation with all materials. For example, if a single process system is used to manufacture different product formulations, the system should be designed based on the explosibility parameters of the most hazardous material. When a large number of different dusts are handled, it may not be possible to test all materials that are handled and selection of the appropriate materials to test should be carefully considered.

In general, representative worst-case samples will be comprised of the driest and finest form of the material present in a given facility. As such, material samples should be obtained from areas where the worst-case particulate will be present, such as dust collection systems.

Guidance for Dust Testing

Explosibility testing is a critical step in dust hazard management. However, it is necessary to ensure that the appropriate tests are performed at the correct conditions to support effective hazard management and mitigation. The following guidance should be followed with respect to combustible dust testing:

- Industrial facilities should always perform testing on material samples obtained from their facility. Given the significant impact of particle size and moisture content on explosibility, literature data is often insufficient to represent the specific explosibility hazards of the material.

- As a conservative approach, the fine fraction of the dust sample should be tested as opposed to the “as received” particle size distribution to quantify the worst-case explosibility parameters of the material for hazard mitigation. The ASTM testing standards recommend testing the material at a particle size distribution of at least 95% minus 200 mesh (75 µm) to account for the worst-case.

- There are certain circumstances when it is appropriate to test materials “as received” in terms of particle size distribution. However, the process conditions and the potential for generation and suspension of fine dust must be considered.

- Dust samples should be obtained from areas where the finest fractions of dust are handled or generated.

- Dusts should be tested at the lowest moisture contents that could be found in the process or facility during normal or abnormal operation. The ASTM testing standards recommend testing the material at a moisture content of less than 5 wt.% to account for the worst-case.

- There are certain circumstances when it is appropriate to test materials “as received” in terms of moisture content. However, the process conditions should be carefully considered along with the potential for moisture content variations due to consistency of operations, environment conditions or material suppliers.

- Dust samples should be obtained from areas where the dryest fractions of dust are handled or generated.

- Industrial facilities should determine which dust explosibility parameters are required to validate their basis for safety and should test the materials accordingly.

- Determining which sample to test and the appropriate sampling locations should be based on careful consideration of the process operations and materials handled.

Our Services

Jensen Hughes owns and operates a state-of-the-art dust explosion lab and can provide comprehensive dust explosibility testing services. Our team can assist with all aspects of the dust testing process to ensure that appropriate explosibility data is obtained for the specific industrial operation or facility. Our dust experts can then use this data to ensure that effective management and mitigation of combustible dust hazards are achieved through the completion of a dust hazard analysis.

References

| [1] | R. K. Eckhoff, Dust Explsoions in the Process Industries, Gulf Professional Publishing, 2003. |

| [2] | G. van Laar and J. Zeeuwen, "On the Minimum Ignition Energy of Dust-Air Mixtures," Archivum Combustionis , no. 5, pp. 145-159, 1985. |

Parker is a Staff Engineer whose technical expertise is focused on industrial process safety. His areas of expertise include performing dust hazard analyses, process hazard analyses, hazardous area classifications, and explosion protection…