Are You Testing your Reactive Chemistry for Emergency Relief System Design?

by Jens Conzen

While everyone wants a safe process safety and emergency relief system, designing such a system can pose challenges. You need to understand the magnitude of potential risks, including a runaway reaction—which can lead to rapid increases in temperature and pressure.

During a recent explosion at a bulk storage tank for crude MDI, the post-accident investigation revealed that a valve was not fully closed or had been damaged. This allowed for leakage of a catalyst into the tank. This caused self-polymerization at a high temperature and the generation of carbon dioxide gas. Eventually, the rising pressure resulted in a fatal explosion.

Pressure build-up in a system may occur because of a process interruption, mischarge, instrument failure, fire or inadequate cooling. These scenarios can result in both vaporization due to exothermic runaway reactions and generation of gasses, which pose a serious threat to the safety of your plant, systems and people.

To be resilient against potential vulnerabilities and threats, it is important to have a properly designed Emergency Relief System (ERS), and to ensure your process has robust passive safety. There are many elements in an ERS design project, but a key feature is known as adiabatic reaction calorimetry testing, where chemical mixtures are tested under quasi-adiabatic conditions.

Adiabatic reaction calorimetry testing is typically performed for facilities that process reactive materials such as chemicals, coatings and pharmaceutical manufacturing. It provides information about the kinetics of a chemical reaction. Typical information obtained from an adiabatic reaction calorimetry test are the character, rate and energy release rates of the chemical reactions, which are essential for safe process design. The benefits include:

- Characterizes material hazards for process safety analyses

- Determines if thermal runaway will occur

- Determine reaction data necessary for vent sizing (e.g. DIERS or ISO 4126-10 methodology) in emergency relief system design

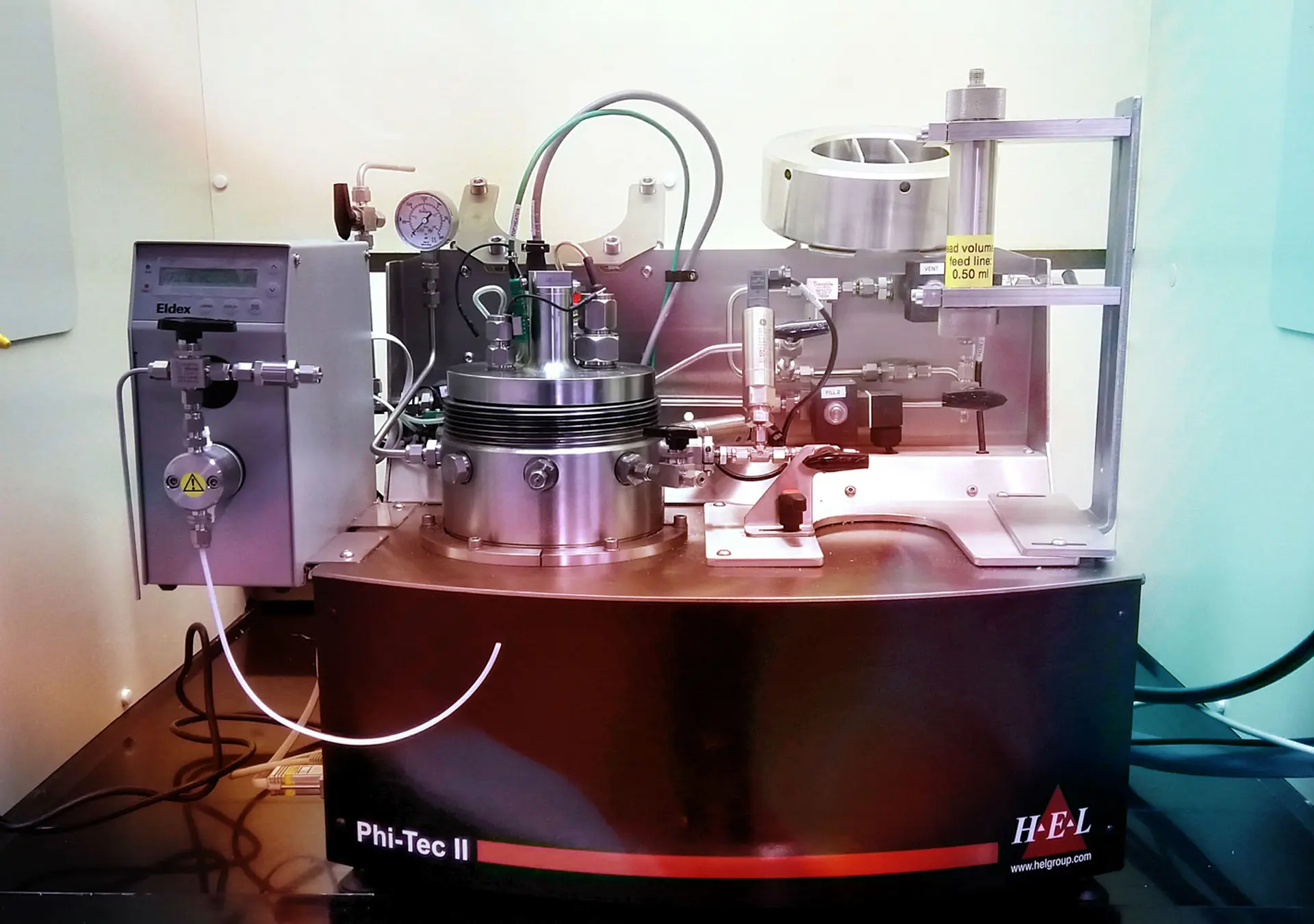

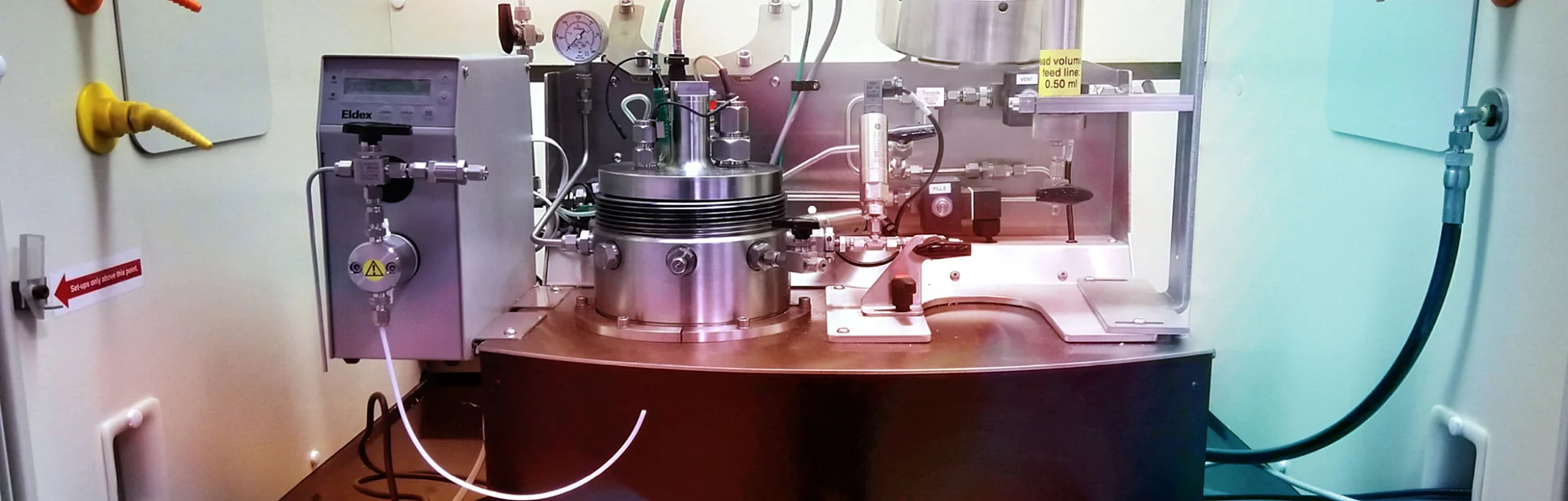

Our in-house process safety lab includes a PHI-TEC II adiabatic calorimetry reactor, which is the required apparatus to conduct these tests. Due to the low thermal inertia of the test cell in our test apparatus, the data can be used directly for full scale test design and has the capability of producing the conditions in large-scale chemical reactors. In a low thermal inertia test device, the test method is nearly adiabatic as required for a full scale analysis. Only a calorimeter such as the PHI-TEC II can deliver the accurate, scalable safety vital for processing from the lab to pilot or plant scale.